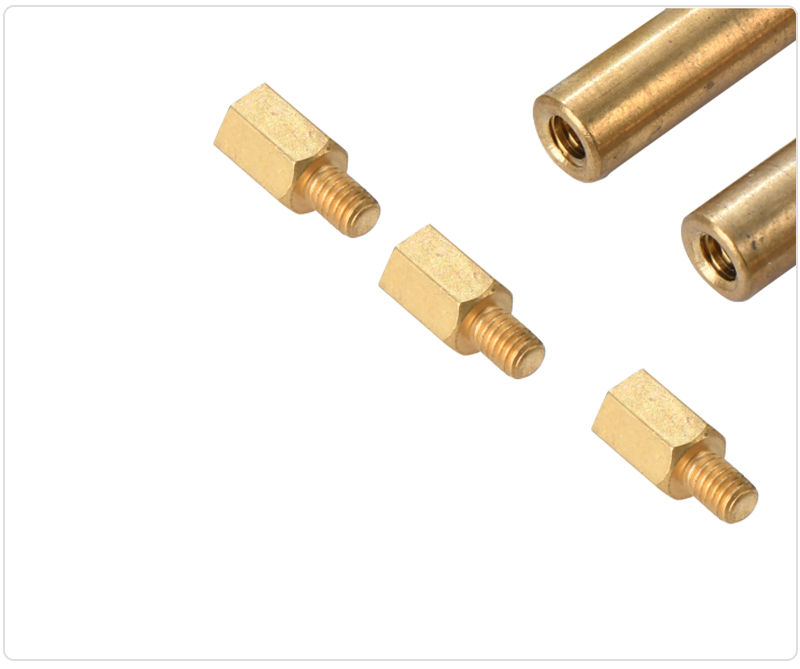

Hexagonal Studs

| Product Number | ALZY0140004 |

| Description | Hexagonal studs |

| Specifications | M3X4+4.7X6 |

| Material | Brass C3604 |

| Surface Treatment | Cleaned to natural color |

| Application Industries | Hardware retail |

CNC Lathe Parts refer to precision components manufactured through CNC turning processes, mainly used for round or rotational parts with strict dimensional and surface finish requirements. At AOYI Hardware, our CNC lathe parts are classified based on product structure, function, and application needs, ensuring customers can quickly find the right components.

High Precision and Consistent Quality

CNC lathe parts deliver exceptional dimensional accuracy and repeatability, ensuring each component meets exact specifications. This precision reduces errors, improves assembly fit, and enhances overall product reliability.

Faster Production and Increased Efficiency

Automated CNC turning significantly speeds up machining cycles compared to manual processes. With optimized tool paths and programmed operations, CNC lathe parts production boosts throughput, shortens lead times, and supports high-volume manufacturing.

Versatility for Complex Designs

CNC lathe parts can be engineered with intricate geometries and tight tolerances that are difficult or impossible to achieve manually. From simple shafts to complex threaded components, CNC turning accommodates diverse shapes with consistent results.

Reduced Labor Costs and Lower Waste

Once programmed, CNC lathes operate with minimal supervision, lowering labor requirements and human error. Precise cutting and efficient material usage also reduce scrap rates, saving raw material costs and improving profitability.

Ruige makes controlling shafts effortless, unlocking limitless application possibilities.

Focusing on carbon steel shaft gaskets, Ruige makes shaft control a breeze, helping customers expand into more innovative application areas.

| Product Number | ALZY0140004 |

| Description | Hexagonal studs |

| Specifications | M3X4+4.7X6 |

| Material | Brass C3604 |

| Surface Treatment | Cleaned to natural color |

| Application Industries | Hardware retail |

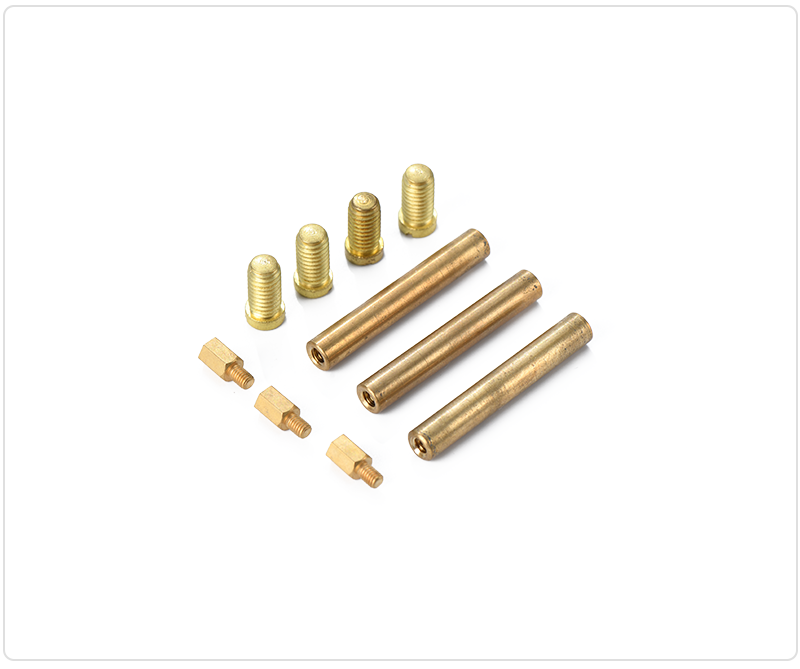

| Product Number | ALSX0150019 |

| Description | Large flathead slotted machine screw |

| Specifications | M6X11.5CM |

| Material | Brasteel H65 |

| Surface Treatment | Alkali-washed natural color |

| Application Industries | Electrical switch |

| Product Number | ALSB0810004 |

| Description | Square step screws |

| Specifications | 3X7CM |

| Material | SCM435 |

| Surface Treatment | Environmentally friendly natural zinc-nickel alloy |

| Application Industries | Electrical appliances |

| Product Number | ALSA0420001 |

| Description | Flathead adjusting screw |

| Specifications | 6X10.65 |

| Material | Brass HPB59 |

| Surface Treatment | Natural brass finish + blue adhesive |

| Application Industries | Doors and windows |

| Product Number | ALSA0280006 |

| Description | Adjusting screw |

| Specifications | M7X8.68 |

| Material | 1215 |

| Surface Treatment | Environmentally friendly copper base nickel |

| Application Industries | Home use |

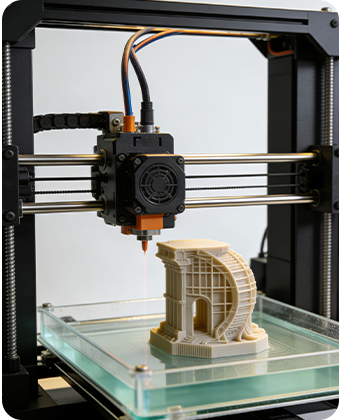

| Product Number | ALMA1190007 |

| Description | Knurled Nuts |

| Specifications | M3X5X4 |

| Material | Brass C3604 |

| Surface Treatment | Passivated Natural Color |

| Application Industries | 3D Printing |

Our products are perfect for home care, beauty salons, and medical use, promoting skin health and wellness

With 18 years in the shaft components industry, Mengpeng covers 80% of market demand and serves over 800 clients, including renowned brands like Huawei, Lenovo, Mindray, and Volkswagen.

Making every rotation smoother and every detail more precise—follow Mengpeng Hardware to explore more possibilities for shafts.

We provide comprehensive customization services for materials, dimensions, tolerances, and surface treatments to meet the high-standard requirements of industries such as consumer electronics, medical devices, and automotive.

With a stock of 90 million standard parts, we support same-day order placement and next-day delivery, ensuring smooth production schedules and minimizing waiting times for our customers.

We offer product selection guidance, process optimization, installation assistance, and application solutions to help customers improve R&D efficiency and reduce production risks.

Washer tolerances can be controlled within 0.03–0.05mm (Higher precision can be achieved at 0.01-0.02mm.), supported by a complete inspection system to ensure every batch of products is stable, reliable, and compliant with industry standards.

Options include anodizing, zinc plating, nickel plating, black oxide, polishing, and sandblasting.

Yes, we support OEM & ODM services based on drawings, samples, or technical requirements.

Standard tolerance can reach ±0.01mm, and tighter tolerances are available upon request.

CNC lathe parts are widely used in automotive, electronics, medical devices, industrial equipment, and hardware industries.

Common materials include aluminum, stainless steel, carbon steel, brass, copper, and engineering plastics.

CNC lathe parts are precision components manufactured using CNC turning machines, mainly for cylindrical or rotational shapes.