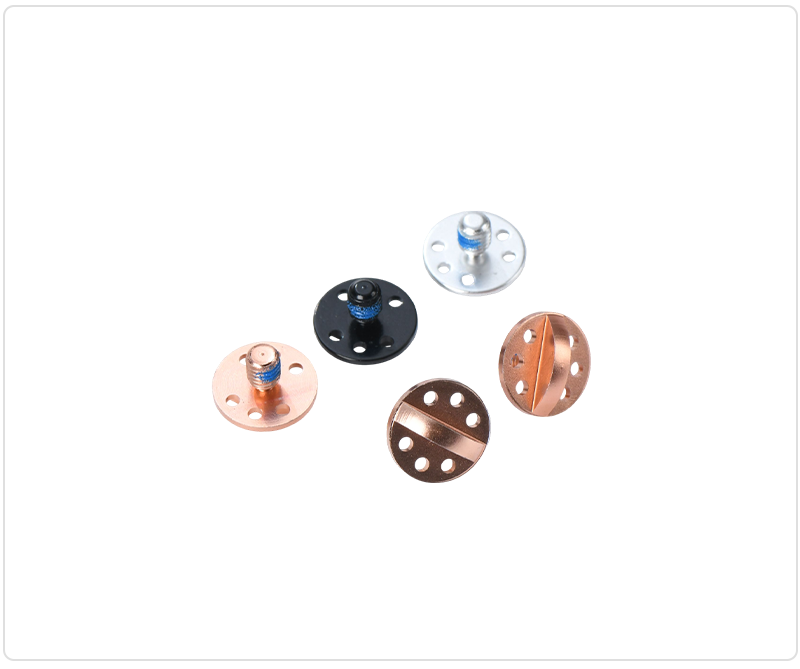

Cup-Head Stepped Quick-Thread Machine Screw

Model:ALSA1110001 | M5×22.3 | Environmentally Friendly Blue Zinc

What Is a Cup-Head Stepped Quick-Thread Machine Screw?

The Cup-Head Stepped Quick-Thread Machine Screw(Model ALSA1110001)is a precision industrial fastener designed for high-efficiency assembly and stable structural positioning.

This Stepped Machine Screw features a cup-shaped head,a stepped shank,and a quick-thread design,enabling fast installation,accurate alignment,and reliable fastening performance.

With a specification of M5×22.3,this Cup Head Stepped Screw is widely used in electronics and industrial equipment,where dimensional accuracy and environmentally compliant surface treatment are required.

Product Specifications

Description | ALSA1110001 |

Specifications | ALSA1110001 M5X22.3 cup-head stepped quick-thread machine screw - HM-1008 - environmentally friendly blue zinc |

Material | M5X22.3 |

Surface Treatment | 1008 |

Application Industries | environmentally friendly blue zinc |

Drawings | electronics |

Manufacturing Process&Working Principle

The Quick-Thread Machine Screw ALSA1110001 is manufactured through a controlled and repeatable process to ensure consistency and performance:

1.Cold Heading Forming

The cup head and stepped shaft are formed in one process,ensuring excellent concentricity and strength.

2.Precision Thread Rolling

The quick-thread profile is rolled(not cut),improving surface hardness and increasing fatigue resistance.

3.Stepped Shaft Processing

The stepped section enables accurate positioning and controlled load transfer during assembly.

4.Surface Treatment–Blue Zinc Plating

An environmentally friendly blue zinc coating is applied to improve corrosion resistance while meeting international environmental standards.

Working Principle:

The stepped shank guides the screw into the correct position,while the quick-thread engages rapidly with the internal thread,delivering strong holding force with fewer rotations than conventional machine screws.

Why Choose Us as Your Stepped Machine Screw Supplier?

Compared with other fastener suppliers,we provide clear B2B advantages:

Extensive experience in precision stepped fasteners

Stable mass-production capability for consistent quality

OEM&drawing-based customization support

Strict material and surface treatment control

Export-focused packaging and documentation

Responsive technical and sales support

We focus on delivering application-ready fastening solutions,not just standard screws.

FAQ

Q1:What makes this Cup Head Stepped Screw different from a normal M5 screw?

The stepped shank improves positioning accuracy and load control,while the quick-thread design enables faster installation.

Q2:Is the blue zinc plating environmentally friendly?

Yes.The surface treatment complies with common environmental standards for electronic applications.

Q3:Can you provide drawings for confirmation?

Yes.Engineering drawings are available for electronic and mechanical verification.

Q4:Is this Quick-Thread Machine Screw suitable for automated assembly?

Absolutely.It is designed for high-efficiency assembly lines.

Q5:Can specifications be customized?

Yes.Length,diameter,material,and surface treatment can be customized based on project needs.