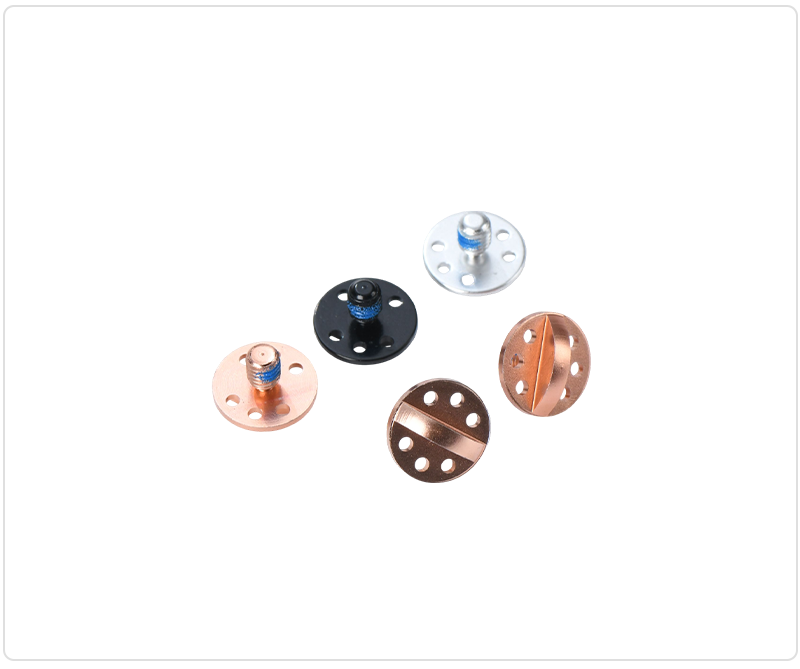

Self-Tapping Semi-Thread Screw for 3D Printing Applications

Product Overview

The Self-Tapping Semi-Thread Screw(ALSA1190104)is a precision fastener engineered for stable and efficient assembly in 3D printing structures.Featuring a flat head internal hex socket,partial thread design,and zinc-nickel alloy surface treatment,this screw provides excellent holding strength,corrosion resistance,and long-term reliability.

This product is also commonly referred to as a Cup Self-Tapping Semi-Thread Screw,Semi Thread Self Tapping Screw,or Partial Thread Self Tapping Screw,depending on regional and industry terminology.

Product Parameters

Product Number | ALSA1190104 |

Description | 3X5.5-CB-1018-Natural Zinc-Nickel Alloy-Flat Head Internal Hex Socket Self-Tapping Semi-Thread Screw |

Specifications | 3x5.5 |

Material | 1018 |

Surface Treatment | Natural Zinc-Nickel Alloy |

Application Industries | 3D Printing |

What Is a Self-Tapping Semi-Thread Screw?

A Self-Tapping Semi-Thread Screw is designed to form its own mating threads during installation,eliminating the need for pre-tapped holes.The partial thread structure allows the unthreaded shank to improve alignment while increasing clamping force between components.

Compared with fully threaded screws,a Partial Thread Self Tapping Screw delivers better axial load distribution and reduces the risk of component deformation—an important factor in precision assemblies such as 3D printer frames and modular parts.

Manufacturing Process&Working Principle

Manufacturing Process

The production of ALSA1190104 follows controlled and standardized steps:

Material Preparation–High-quality 1018 carbon steel is selected for strength and consistency.

Cold Heading–The flat head and internal hex socket are formed with high dimensional accuracy.

Thread Rolling–Semi-thread profiles are rolled to improve fatigue resistance and thread integrity.

Self-Tapping Profile Forming–Special thread geometry enables effective thread forming in base materials.

Zinc-Nickel Alloy Plating–Enhances corrosion resistance and surface durability.

Quality Inspection–Dimensional accuracy,torque performance,and coating thickness are tested.

Working Principle

When driven into the material,the Cup Self-Tapping Semi-Thread Screw cuts or forms threads while the unthreaded section generates higher clamping force.This ensures secure fastening,reduced loosening,and stable performance over time.

Why Choose Us as Your Self-Tapping Screw Supplier?

Our Supplier Advantages

Strict Quality Management–Each batch is inspected for consistency

OEM&Custom Solutions–Size,coating,and packaging customization available

Fast B2B Response–Technical support for application-specific requirements

Stable Production Capacity–Reliable lead times for bulk orders

Export Experience–Familiar with global fastener standards and expectations

Compared with general fastener traders,we focus on engineering accuracy,application suitability,and long-term supply stability.

FAQ

Q1:What is the main advantage of a semi-thread design?

A semi-thread design improves clamping force and alignment while reducing stress on assembled parts.

Q2:Is this screw suitable for plastic used in 3D printing?

Yes.The self-tapping profile is designed for commonly used 3D printing plastics and light metals.

Q3:Can this product be customized?

Yes.We support OEM customization including size,surface treatment,and packaging.

Q4:How does zinc-nickel coating benefit this screw?

It provides superior corrosion resistance and longer service life compared to standard zinc plating.

Q5:Is this suitable for B2B bulk purchasing?

Yes.This product is designed specifically for industrial and B2B supply chains.