What Is Cold Heading Process in Fastener Manufacturing?

When it comes to large-scale fastener production, manufacturers are constantly balancing strength, precision, cost, and efficiency. One of the most widely used processes to achieve this balance is cold heading.

But what exactly is cold heading, how does it work, and why do so many fastener manufacturers rely on it instead of machining? This article will walk you through the cold heading process in fastener manufacturing, its advantages, applications, and how to decide whether it’s the right choice for your project.

What Is Cold Heading?

Cold heading (also called cold forming) is a metal forming process in which wire or rod material is shaped into fasteners at room temperature, using high-speed dies and punches.

Unlike CNC machining, cold heading does not cut material away. Instead, it forces the metal to flow into the desired shape under high pressure. This allows manufacturers to produce screws, Bolts, studs, and Rivets with high strength and consistent dimensions.

Cold heading is especially common in the production of:

Screws

Rivets

Studs & Rods

Standard and custom fasteners

How the Cold Heading Process Works

Although cold heading machines operate at extremely high speeds, the process itself follows a clear sequence:

1. Raw Material Preparation

The process starts with metal wire coils, commonly made from:

Carbon steel

Stainless steel

Alloy steel

Brass or aluminum (for specific applications)

The wire is straightened and cut into precise lengths, known as blanks.

2. Heading and Forming

The blank is fed into a cold heading machine, where one or multiple blows from punches force the metal into a die cavity. This step forms the head of the fastener, such as:

Hex head

Pan head

Flat head

Button head

For complex shapes, multi-station cold heading machines are used, allowing progressive forming in several steps.

3. Secondary Operations (If Needed)

After heading, additional processes may be applied:

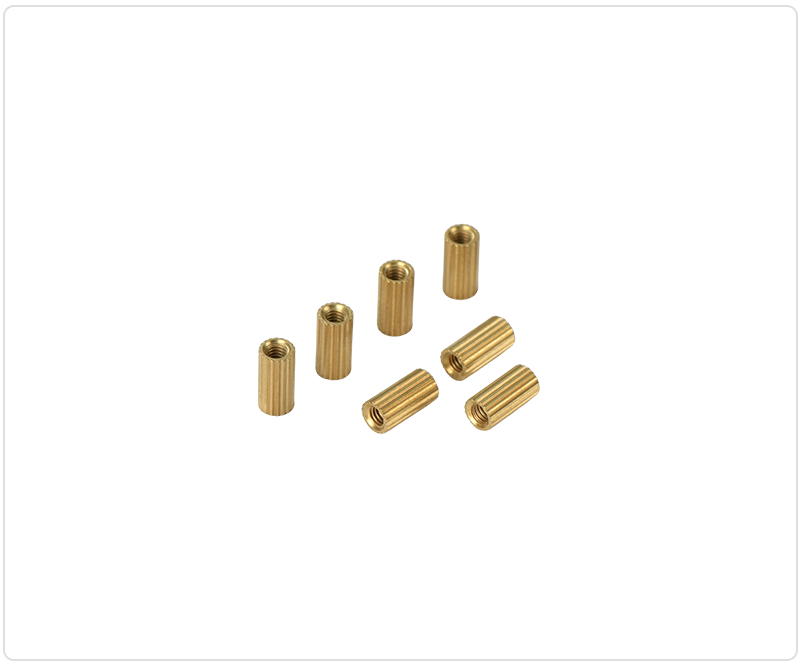

Thread rolling

Knurling

Point forming

Slot or recess forming (Phillips, Torx, Hex socket)

Thread rolling is particularly important, as it further increases the fastener’s strength by compressing the metal rather than cutting it.

4. Heat Treatment & Surface Finishing

Depending on the application, fasteners may undergo:

Heat treatment for hardness and tensile strength

Surface treatments such as zinc plating, nickel plating, black oxide, or passivation

Why Cold Heading Is Preferred in Fastener Manufacturing

Cold heading is not just about speed—it delivers structural and economic advantages that other methods struggle to match.

1. Higher Strength

Because the metal grain structure flows along the shape of the fastener instead of being cut, cold headed fasteners offer:

Higher tensile strength

Better fatigue resistance

Improved durability under load

This makes cold heading ideal for automotive, industrial, and structural applications.

2. Material Efficiency

Cold heading produces minimal waste. Almost all raw material becomes part of the final product, unlike CNC machining, where excess material is removed as chips. Lower waste = lower material cost.

3. Consistency in Mass Production

Once tooling is set, cold heading machines can produce thousands of identical fasteners per hour, ensuring:

Tight dimensional tolerances

Stable quality across large batches

Reduced unit cost at scale

4. Cost-Effective for High Volumes

Although tooling costs are higher upfront, cold heading becomes far more economical than machining when producing medium to large quantities.

Cold Heading vs CNC Machining: What’s the Difference?

Both processes are widely used, but they serve different purposes.

Cold Heading is best for:

High-volume production

Standard or semi-standard fasteners

Parts requiring high strength

Lower cost per unit at scale

CNC Machining is better for:

Low-volume or prototype orders

Complex geometries

Tight tolerances on unique features

Fast design changes

Many professional fastener manufacturers use both processes, choosing the most suitable method based on design, volume, and performance requirements.

Applications of Cold Headed Fasteners

Cold headed fasteners are found in nearly every industrial sector, including:

Automotive manufacturing: Engine components, chassis assemblies, braking systems

Industrial equipment: Machinery frames, motors, mechanical assemblies

Home appliances: Washing machines, refrigerators, HVAC systems

Electronics & electrical equipment: Structural and grounding fasteners

Materials Commonly Used in Cold Heading

Material selection plays a critical role in cold heading success. Common choices include:

Carbon steel: cost-effective, suitable for general applications

Stainless steel: corrosion resistance for harsh environments

Alloy steel: high strength requirements

Brass / Aluminum: lightweight or conductive applications

A professional cold heading fastener manufacturer will help evaluate material flow characteristics to ensure proper forming without cracking or defects.

When Should You Choose Cold Heading?

Cold heading is the right choice if:

You need large production volumes

Strength and consistency are critical

Cost efficiency matters

The design is suitable for forming

If your project involves complex features, low quantities, or frequent design changes, CNC machining may be more appropriate.

Why Work with an Experienced Cold Heading Fastener Manufacturer?

Cold heading is highly dependent on:

Tooling design

Machine setup

Material selection

Quality control

An experienced manufacturer can:

Optimize fastener design for forming

Reduce tooling and production risks

Ensure stable quality across large orders

Provide OEM and custom fastener solutions

Choosing the right partner directly impacts product performance and long-term reliability.